Kafa a shekara ta 2009, Alicosarar da aka kirkira, kayayyaki, da tsarin iko, da yawa tsunduma cikin bincike da ci gaba, samarwa da kuma tallace-tallace na PV kayayyaki; tashoshin wutar lantarki da samfuran samfuran da sauransu na PV ɗin ta PV ɗin ya wuce 80GW.

Tun da yake a 2018, Alicosolarin yana fadada Kasuwanci ya hada da Kasuwancin Solar, Taskar Shirin, gini, ayyukan da sarrafawa, da hanyoyin haɗi na tsarin tsayawa don abokan ciniki. Alicosar ya haɗa sama da 2.5GW na wutar lantarki na hasken rana zuwa grid a duk duniya.

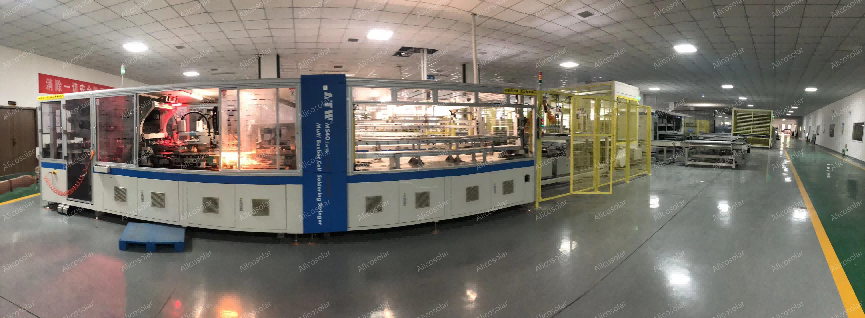

Shagon aikinmu

Gidan yanar gizon mu

Duk aji na hasken rana, ya hana daga dubawa

Mataki na 1-Laser Combliba, muhimmanci yana ƙaruwa da wafer fitarwa a kowane sashi taro

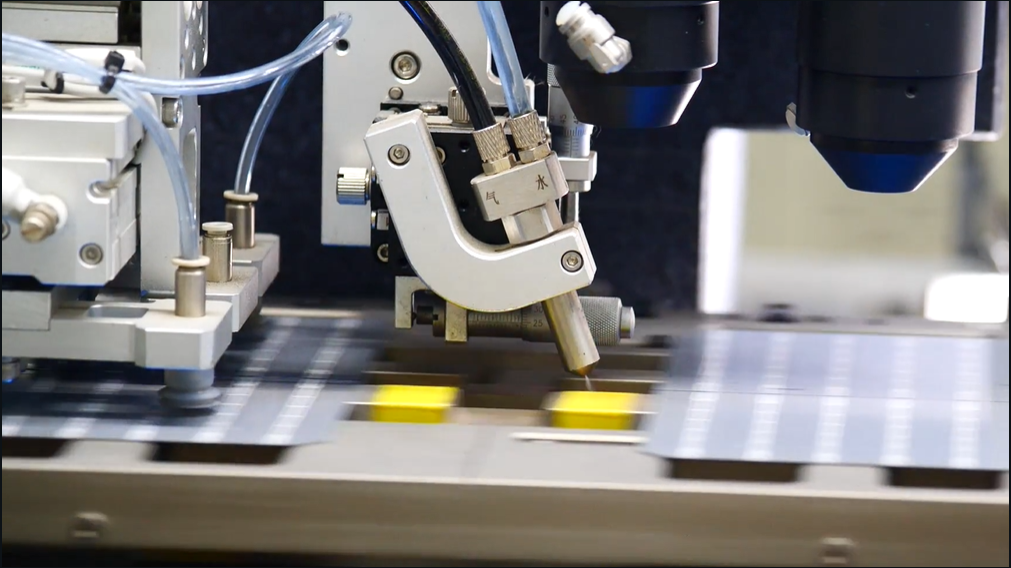

Mataki 2-kirtani Welding

A lokacin da ciwon kai ar inarfin gilashin, eva sannan kuma tari mai zafi na jira

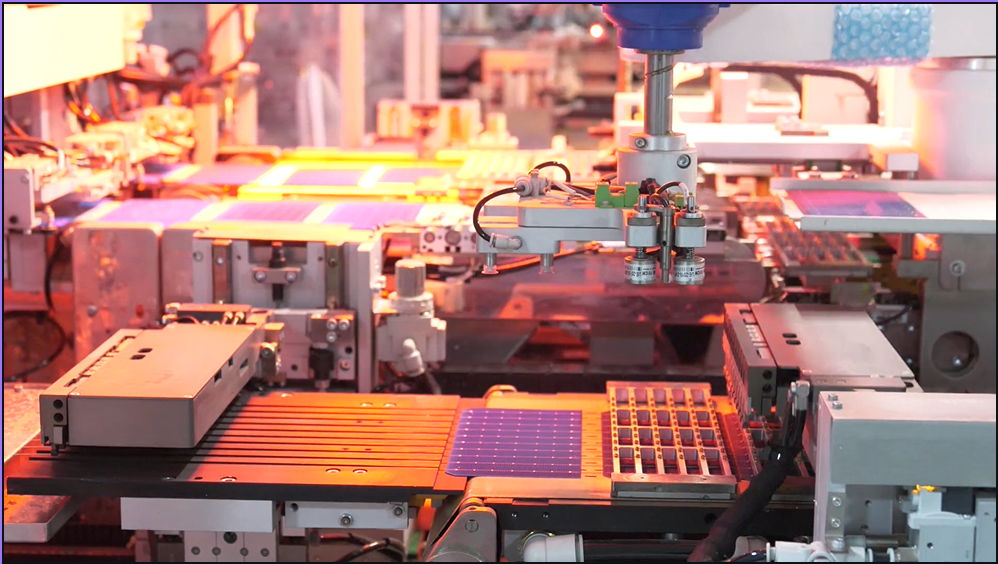

Mataki na 3-atomatik Instetetsetseteteting a kan gilashin jira da eva

Mataki na 4-dagarated Welding da Lamation.

Yi amfani da injin da aka ɓata mai zurfi (kayan aiki daban don sel daban-daban masu girma) don wallel tsakiyar sel fruit, kuma yin saitin hoto, sannan a haɗa hoto ta atomatik don sakewa.

Mataki na 5 - Gilashin, Eva, an ajiye su bisa ga wani matakin kuma a shirye take, Eva, Farin Baturi, Kasuwanci).

Mataki na 6-bayyanar da gwajin el

Dubawa ko akwai ƙananan kwari, ko an fasa baturin, sananniyar sel, sel da sauransu zasu dawo.

Mataki na 7-Laminated

Gilashin da aka lido / Strow Stret / Eva / Back Sheet pre-latsa zai kwarara ta atomatik ta atomatik, kuma ga Eva za a narke ta hanyar dadawa don ɗaure baturin, gilashin da Shafar baya tare, kuma a ƙarshe cire taron don sanyaya. Tsarin lamation shine mabuɗin babban mataki a cikin samar da abubuwan da aka gyara, da lokacin zazzabi da lokacin zafin jiki da kuma jin zafin rana an ƙaddara bisa ga kadarorin Eva. Lokacin kewayawa shine kimanin minti 15 zuwa 20. Zaɓin zafin jiki shine 135 ~ 145 ° C.

Gudanar da Prince Products: kumfa na iska, karce, ramuka, bulges da kuma faɗakarwa

Mataki na 8-Module aiwatar da gyaran

Bayan lamination, bangarorin da ke gudana zuwa firam, kuma bango na ciki bango na ciki ana bugun ta kai tsaye kuma an ɗora firam atomatik. Sassan abubuwa na abubuwan da suka dace don shigarwa na injiniya.

Babban ikon sarrafawa: ramuka, scratches, scratches, manne a ƙasa, kumfa shigarwa da ƙarancin karancin rauni.

Mataki 9 -gity

Abubuwan haɗin da aka haɗa tare da firam da akwatin maɓallin shigar a cikin tashar gaba ana saka su cikin layin da ke cikin injin canja wuri. Babban dalilin shine warkar da seolant allon idan an sanya firam ɗin da kuma akwatin lakabin kuma kare abubuwan da ke cikin matsanancin yanayi. tasirin.

Babban ikon sarrafawa: Lokaci na warkarwa, zazzabi da zafi.

Mataki na 10-tsaftacewa

Tsarin kayan aiki da akwatin jiko na fitowa daga layin cirewa an haɗa shi cikakke tare, kuma an sami sealant. Ta hanyar injin juyawa na 360, manufar tsaftace gaban bangarorin da aka samu a jerin taro a kan layin taro. Ya dace don tattara fayil a bayan gwajin na gaba.

Babban sarrafa tsari: Scratches, scratches, jikin kasashen waje.

Mataki na 11-gwaji

Auna sigogin wasan kwaikwayon na lantarki don tantance matakin kayan aiki. LV gwajin - auna sigogi na lantarki don tantance matakin kayan aikin.

Lokaci: Jul-28-2022